|

|

|

| |

| |

| |

| |

| |

| |

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

ÂÑÑ-ÂÑ

deposited

Diamond Like Carbon (DLC) ultra thin and thin

films and nano coatings on different substrates,

such as :

** SS-316 LMV,

** Teflon,

** Ceramics,

** Semiconductor materials for infrared optics

(Si, GaAs, Ge and ZnSe as well.).

Cardiovascular Implants (stents) made of SS-316

and Nitinol have been coated by ultra thin and

thin film ta-C and a-C

types of DLC .

Further

development of the technology resulted in obtaining

ultra hydrophobic hybrid material - polymer (teflon)/DLC,

coated as thin and ultra thin films on metal substrate

- SS 316 LVM Stent.

The quality of the deposited films and the properties

of the new material have been examined. |

|

|

| non-coated

stainless steel surface |

DLC

coated stainless steel surface |

Human

immune-competent blood cells after 30 min under

arterial shear conditions |

|

|

DLC

coated SS 316 LVM Stent |

|

DLC

coated Nitinol Stent |

|

Teflon

DLC coated |

|

Teflon

graft DLC coated |

|

Teflon

/ ta-C DLC coated |

|

|

| |

|

|

|

|

|

|

|

| |

|

|

Metal

nanoparticles of Silver and Platinum have been

incorporated within the DLC matrix coatings on

cardiovascular stents.

Researchers published info that "...DLC-silver

and DLC-platinum composite films reveals ... self-assemble

into particulate nano composite structures that

possess a high fraction of sp3-hybridized carbon

atoms. DLC-silver-platinum films demonstrated

exceptional antimicrobial properties ."

|

|

|

MDLC

coated Stent and

nonCoated Stent

|

|

|

| |

|

|

|

|

|

| |

|

|

Radiopaque Stent

|

BCC-BC

has developed and manufactured a radiopaque stent.

SS 316 LVM stent has been coated by thin film -

50 nm ta-C type of DLC and

within the same process metal nano particles of

platinum have been incorporated within the DLC structure.

By standard X-ray procedure, two sample stents coated

by DLC and by MDLC have demonstrated substantially

different radiopaque capabilities - MDLC is better

visible under x-ray.

Radiopacity is one of the key considerations in

the design of various devices such as stents that

are used during radiological control on cardiovascular

intervention. |

|

|

MDLC

coated and

DLC coated Stents

|

|

|

| |

|

|

|

|

|

| |

|

|

ÂÑÑ-ÂÑ

has developed a new applied technology for deposition

of ultra thin and thin films DLC (a-C and ta-C types)

on Nitinol stent.

|

|

|

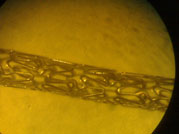

DLC

coated Nitinol Stent

0.1 and 10 microns resolution

|

|

|

| |

|

| |

|

|

|

|

|

| |

|

|

Depositing

thin and ultra thin films of polymer P-312 (our

designation), from the family of phosphonats on

ceramic and metal substrates, besides known properties,

such as biocompatibility and biodegradability a

strongly manifested photoluminescence has been observed.

The polymer has mol.w. 12,500 Dalton.

These biodegradable polyphosphoesters are appealing

for biological and pharmaceutical applications,

because of their biocompatibility and similarity

to bio-macromolecules such as nucleic acids.

Intensive research and development of P-312 potential

and properties is in progress.

|

The

polymer has been successfully coated on stainless

steel sheets. The coatings are smooth, uniform and

have a good adherence. After 75-days storage at

ambient conditions biodegradation of the coating

can be observed. |

|

|

|

P

- 312 Polymer

photoluminescence

|

| |

|

P

- 312 Polymer coated |

|

|

| |

| |

|

|

|

|

|

| |

|

|

ÂÑÑ-ÂÑ

has

started depositions of biocompatible and biodegradable

nano coats, based on P-329 natural biopolymer Polyhydroxybutyrate

(PHB) and its co-polymers, on DLC coated cardiovascular

stent.

By using the STÚLB™ technology, a stainless steel

stent has been uniformly coated with a 80 nm film

of PHB. The coating has a good adherence, is smooth

and without cracks.

By

the STÚLB™ technology ÂÑÑ-ÂÑ is capable to coat

up to 50 stents within 60 min.

P-329 nano films might be coated (sandwich) by an

ultra thin layer of biodegradable and biocompatible

metal alloy M-014

|

|

|

|

|

P

- 329 Polymer

deposited as 80 nm film on SS 316

|

|

|

| |

|

| |

|

|

|

|

|

| |

|

|

BCC-BC

has

done controllable deposition of complex biopolymer

material known as Myoglobin - protein with mol.

w. 17400 Dalton. Thin films have been coated without

risk of damaging protein's properties onto many

substrates. Myoglobin thin films have been subject

to quantified using Fourier Transform Infrared Spectroscopy

(FTIR) for comparisons to native materials.

|

|

|

|

FTIR

Myoglobin - native |

|

FTIR

Myoglobin thin film

|

|

|

| |

|

|

|

|

|

| |

|

|

BCC-BC

is

performing controllable deposition of complex polymers

and organic materials. Deposition on PLGA resomer

RG 503 H – synthetic biodegradable and biocompatible

polymer in nano coats. The material is applied in

pharmaceutics and DES. Multi-layered films are deposited

without any risk of harming the deposited material

properties onto any surface. Polymer bone structure

analysis of these films have been quantified using

Fourier Transform Infrared Spectroscopy (FTIR) for

comparisons with native materials.

|

|

|

|

|

SEM

(Scanning Electron microscope)

PGLA film deposited by means of laser technology

on SS substrate |

|

FTIR

PLGA - native |

|

FTIR

PLGA thin film

|

|

|

| |

|

| |

|

|

|

|

|

| |

|

|

BCC-BC

has started testing ultra thin PET polymeric films

on standard testing substrates, for heavy metal

detection sensor device.

The Polymer D 712 (our designation

name) and some of it's generations have shown

properties usable for highly sensitive sensors and

display utilities, made in form of ultra

thin

and thin films..

Looking for cooperation and partnership within FP7

of EU.

|

|

|

|

D

712 |

|

D

712 Second Generation

|

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

|